SIN YANG PLASTICS

Crafting the Future of Plastic Hardware

We offer a wide range of innovative plastic hardware products that shape modern living. Our expertly designed solutions meet the evolving demands of today’s industry, ensuring both reliability and sustainability.

About Sin Yang

Tailored Solutions for Every Need

Moulding its beliefs on customer-centric approach, Our company approaching since year 1998 establishment, is discovering new ways of meeting and fulfilling the market demands. The core business of Sin Yang Plastic Enterprise Sdn Bhd is producing and manufacturing various kinds of plastic products, this includes in-house products & custom made products. The company’s core philosophy of continuously evolving with the market trend has enabled it to provide a sound competition to the market.

To remain at the forefront of plastic hardware innovation by embracing new technologies and continuously improving our product line to meet market trends.

Sin Yang Plastic envisions a share in the global market by placing a strict Quality Control (QC) in its every effort to ensure superiority in its products and services in order to capture more internationally based customers.

Leading Plastic Hardware Solutions to Meet Market Demands

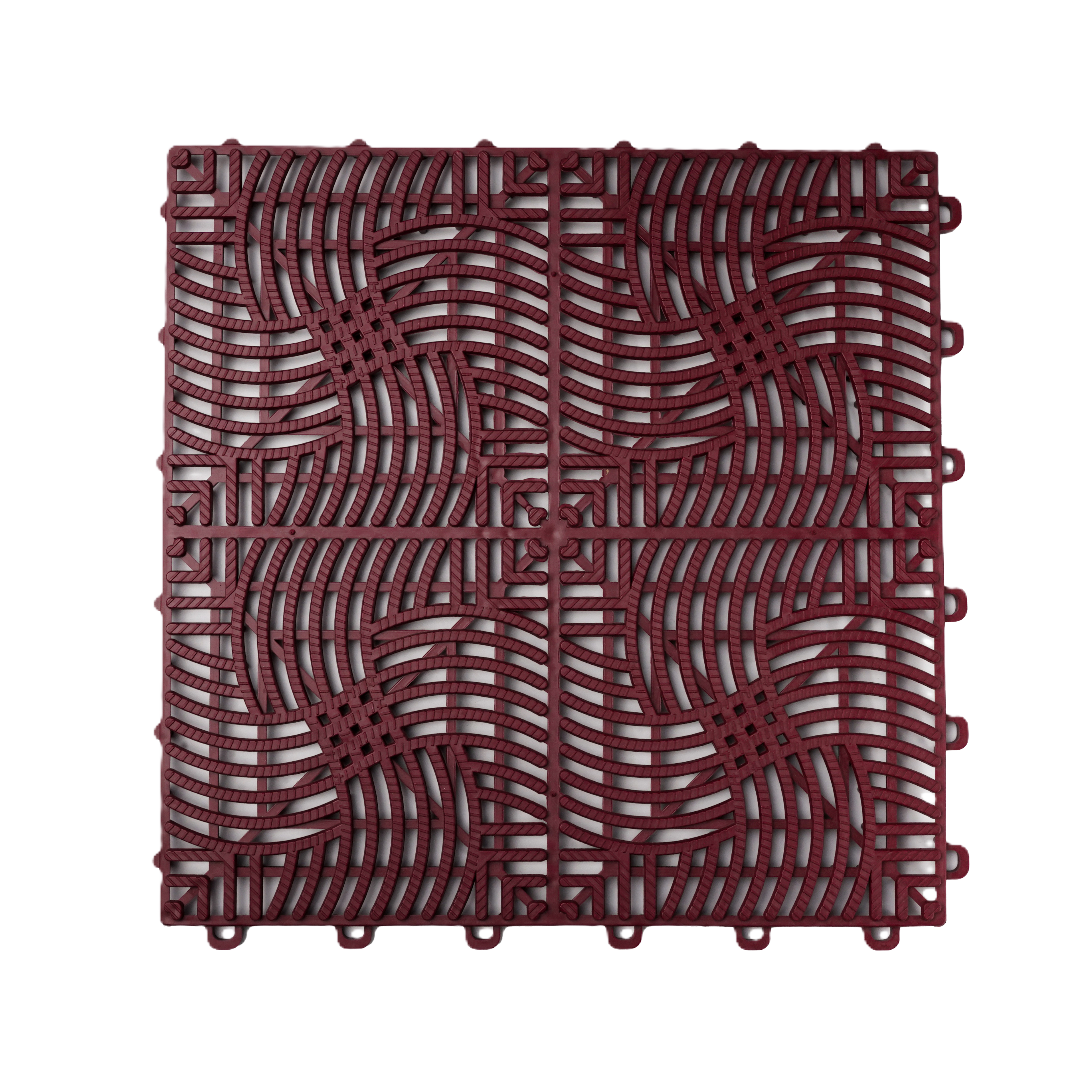

Explore Our Product Range ?

Our products include top-quality plastic components engineered for a variety of applications. View more of our collection and discover the perfect solution for your needs.

Our Products

Our Services

Provide Best Plastic Services

We provide a full range of plastic services, from manufacturing to custom designs, ensuring that all your plastic hardware needs are met with precision. Our expert team is dedicated to delivering high-quality solutions, whether you need prototypes, molds, or large-scale production.

Full-service plastic company

Focus on the plastic hardware needs

Construct a prototype and build custom mold

Full-service plastic company

Focus on the plastic hardware needs

Construct a prototype and build custom mold

Steps to Get a Quote

Step 1 : Browse Our Capabilities

Explore our B2B service offerings. OEM manufacturing, custom formulation, packaging solutions, and contract production. Use filters to find capabilities by industry (food, plastics, packaging, supplements) and certifications (HALAL, GMP, HACCP).

Step 2 : Prepare Your Requirements

Compile your brief: product specs, desired MOQ, target finish, packaging format, and target price. The more details you provide (formula, sample, or tech drawing), the faster we can create an accurate quote.

Step 3 : Request a Quote

Submit a quote request via the online form or upload your spec sheet. We’ll review lead time, MOQ, and production capacity, then respond with a tailored commercial proposal and estimated timeline.

Step 4 : Approve Sample & Contract

We’ll prepare a production sample or mockup for your approval. Once you confirm the sample and terms (pricing, payment schedule, delivery terms), we’ll issue the pro forma invoice and production contract.

Step 5 : Production & Quality Control

After confirmation, manufacturing begins. Our factory follows strict QC processes in-line inspection, finished product testing, and packaging checks. You’ll receive production updates and photos during critical milestones.

Step 6 : Delivery, Handover & Aftercare

We arrange shipment and door-to-door delivery or coordinate with your freight forwarder. Post-delivery, we provide aftercare support for reorders, scale-up planning, and any warranty or quality inquiries.

FAQs

What are the advantages of plastics hardware compared to metal hardware?

Plastics hardware is lightweight, corrosion-resistant, and cost-effective. It does not rust, offers good chemical resistance, and is suitable for applications where weight reduction and insulation are important.

What materials are commonly used for plastics hardware?

Plastics hardware is commonly made from materials such as ABS, PP, PE, Nylon (PA), PVC, and POM. Each material provides different performance characteristics depending on strength, flexibility, and environmental requirements.

Can plastics hardware be customized for specific applications?

Yes, plastics hardware can be customized in terms of size, shape, colour, and material. Custom moulding allows products to meet specific technical and industry requirements.

Which industries commonly use plastics hardware?

Plastics hardware is widely used in manufacturing, electronics, furniture, construction, automotive, and packaging industries due to its versatility and durability.

Is plastics hardware suitable for outdoor or industrial use?

Yes, certain plastics hardware materials are suitable for outdoor and industrial environments. When the correct material is selected, plastics hardware offers resistance to moisture, chemicals, and wear.

How do I choose the right plastics hardware for my application?

Choosing the right plastics hardware depends on factors such as load requirements, operating environment, temperature, and chemical exposure. Professional consultation helps ensure optimal performance and durability.

Interested In Our Service?

Contact us

We’re here to help! Reach out to us for more information on how our plastic hardware solutions can enhance your operations.