OEM Products & Manufacturing Services in Malaysia

At Sin Yang Plastic, we deliver premium OEM products in Malaysia, serving industries from food & beverage to industrial packaging. As a trusted OEM manufacturer and company in Malaysia, we provide custom designs, advanced production, and reliable quality to turn your ideas into reality.

What Are OEM Products?

OEM stands for Original Equipment Manufacturer a company that produces goods for another brand to sell under its own name. OEM products are designed and manufactured based on a client’s specifications, ensuring the final product matches their brand identity, quality standards, and market needs.

Choosing an OEM manufacturer in Malaysia allows businesses to access expert production facilities, reduce setup costs, and bring products to market faster without building their own factories. From concept to completion, OEM manufacturing provides flexibility, scalability, and professional quality for a wide range of industries.

Our OEM Services in Malaysia

At Sin Yang Plastic, we provide complete OEM manufacturing solutions to help your brand bring products to life with precision, quality, and efficiency. As a leading OEM manufacturer in Malaysia, our services cover every stage from concept to delivery, ensuring your products meet industry standards and customer expectations.

SUSTAINABLE SOLUTIONS

We offer eco-friendly OEM manufacturing options, using recyclable materials and energy-efficient processes to reduce environmental impact while maintaining product quality.

QUALITY CONTROL

Every OEM product undergoes strict quality control inspections to ensure compliance with international standards, durability, and customer satisfaction.

PROTOTYPE DEVELOPMENT

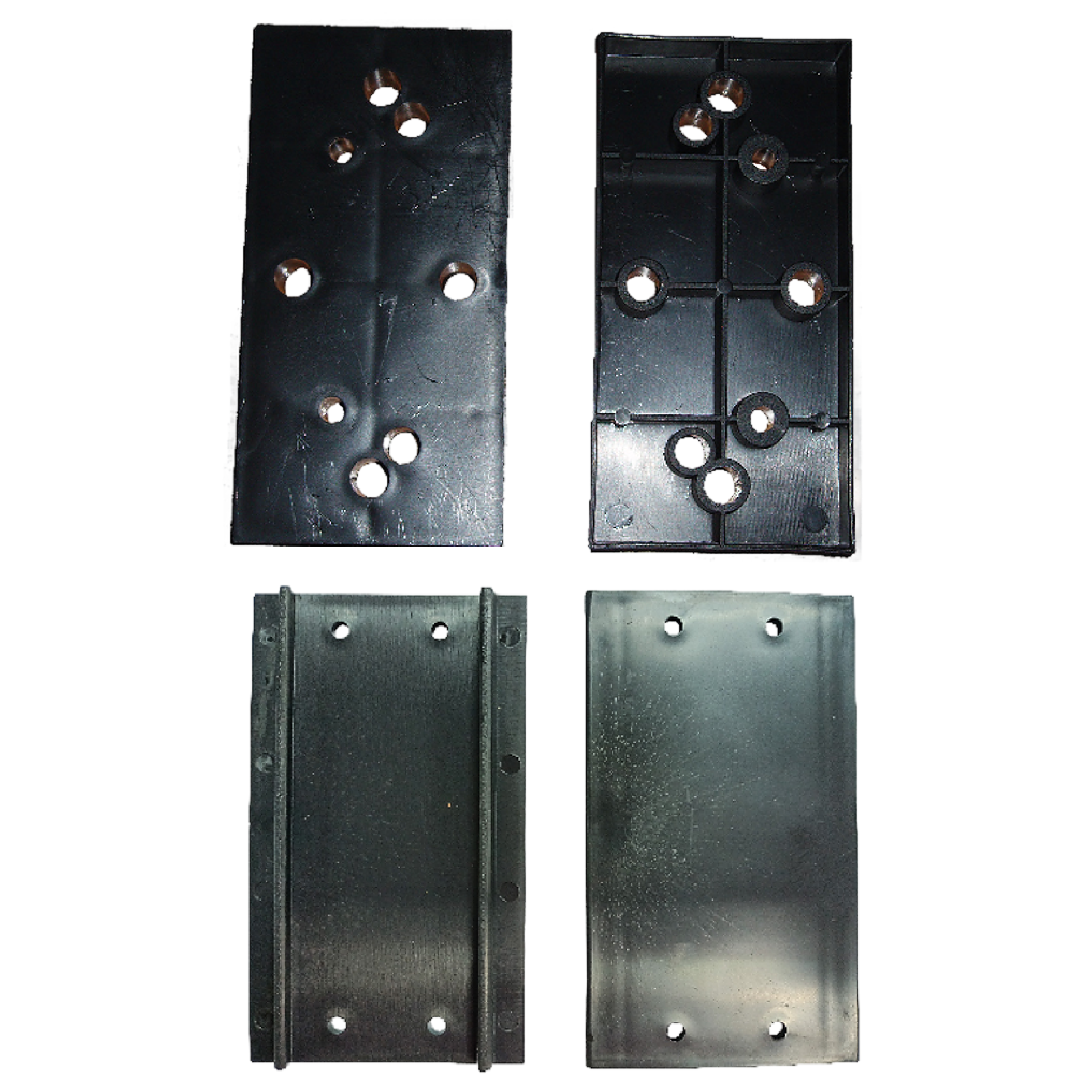

Before mass production, we create functional prototypes to test product design, fit, and performance, ensuring the final product meets your expectations.

Why Choose Sin Yang Plastic as Your OEM Manufacturer in Malaysia?

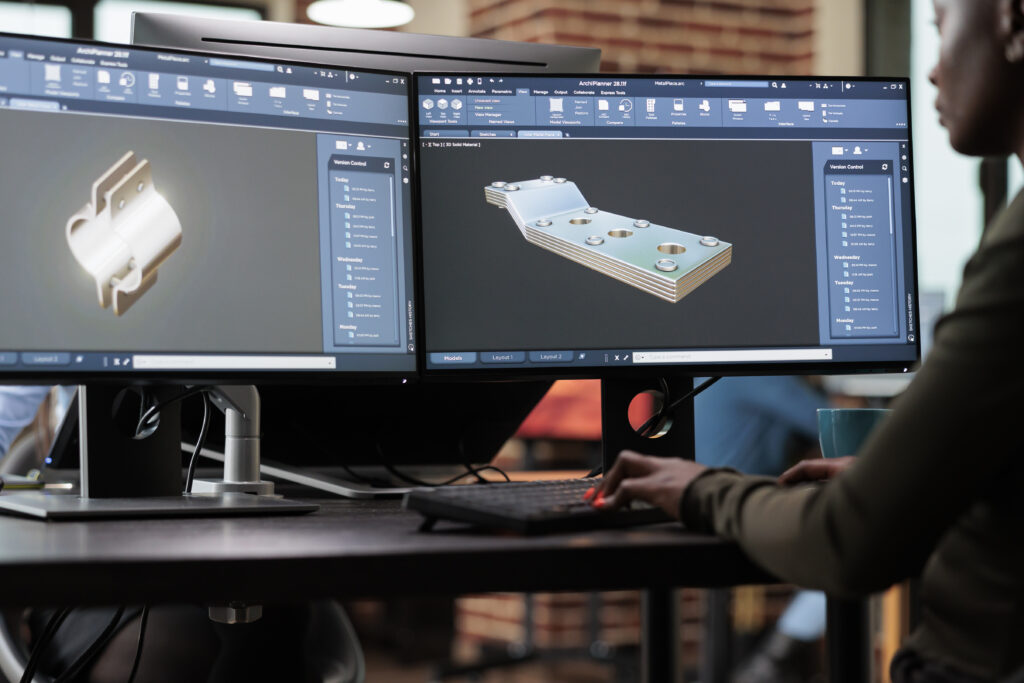

100% In-house design.

100% mold modification.

19 machines (up to 560-ton).

Only 8 weeks to completion.

Your Project Will Be A Success

Sin Yang Plastic has cutting-edge technology and facilities for plastic injection moulding. Sin Yang Plastic comprises not 1 but 2 manufacturing plants and a warehouse.

Our OEM Process

At Sin Yang Plastic, we follow a clear, efficient process to turn your concept into high-quality OEM products in Malaysia. Every step is handled by our experienced team, ensuring precision, speed, and compliance with your specifications.

1

Research & Development

We assist in reducing costs and time during the product development phase.

2

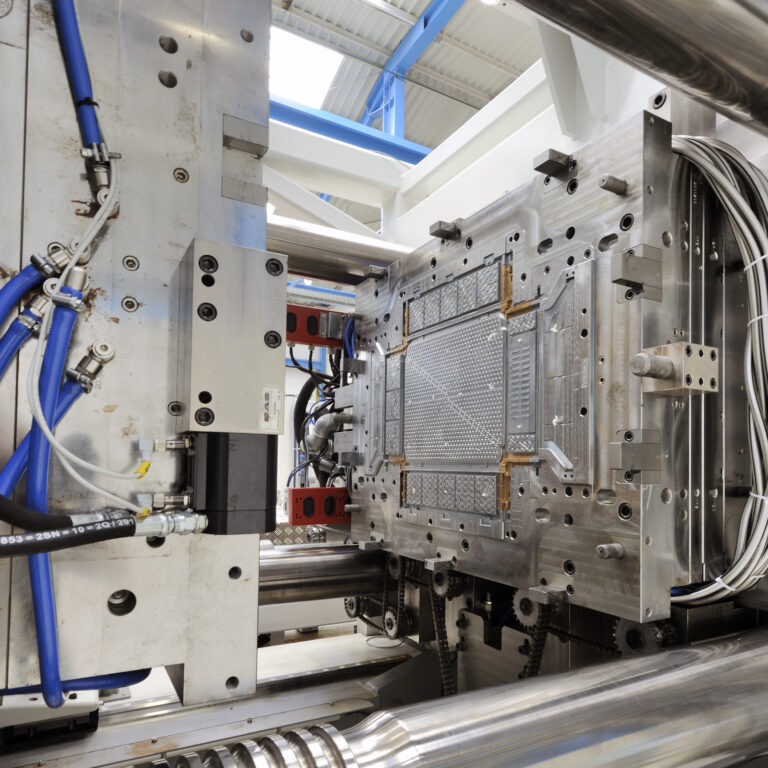

Precision Tooling

We specialize in professional plastic injection mold manufacturing services.

3

Injection Molding Technologies

Sin Yang Plastic offers insert molding and gas-assisted injection molding to create a wide range of products.

4

Secondary Processes

We enhance the results of primary manufacturing processes to deliver high-quality finished products.

5

Maintenance & Repair

Proper maintenance and repair ensure molds remain operational and efficient.

6

QA & QC

Our in-house testing facility guarantees that every part we manufacture meets high-quality standards and customer expectations.

FAQs

Find quick answers to the most common questions about our OEM products in Malaysia, including minimum order quantities, certifications, Halal compliance, and production timelines. This section helps you understand how our OEM manufacturing services work from start to finish.

What’s the MOQ for OEM manufacturing?

Our MOQ depends on the product type and specifications, but we strive to offer flexible quantities to support both small and large-scale production in Malaysia.

Do you have GMP or ISO certifications?

Yes. As a trusted OEM manufacturer in Malaysia, we comply with strict quality standards and hold relevant certifications, including GMP and ISO, to ensure product safety and consistency.

Can you handle Halal-certified production?

Absolutely. We can produce OEM products under Halal-certified processes, meeting the requirements for Muslim consumer markets locally and internationally.

What turnaround time can I expect?

Depending on complexity, our OEM manufacturing process can be completed in as little as 8 weeks, from concept to finished product.

Start Your OEM Project Today

Partner with Sin Yang Plastic, a trusted OEM manufacturer in Malaysia, to bring your product ideas to life. From concept to delivery, we provide quality, customization, and reliable service every step of the way. Contact us today to discuss your requirements and get a tailored quotation.